[vc_row][vc_column][vc_column_text css_animation=”fadeIn” css=”.vc_custom_1688530547569{background-image: url(https://www.weedtechnics.com/wp-content/uploads/2020/07/Flame-Thower-4.jpg?id=2873) !important;background-position: 0 0 !important;background-repeat: no-repeat !important;border-radius: 2px !important;}”]

There’s a question that comes up in just about every introductory conversation

“What do you do for work?“Who else can say, “I kill weeds with steam!“

The responses I hear run along the lines of

‘WOW! I didn’t know you could do that!‘Is it an organic weed killer?’‘What, so you just cook the weeds?’‘Hey, that’s a great idea, No Poisons!’‘Steam! Does that really work?’

Well actually “YES IT DOES”, but there is a little more to it than it sounds…

Universally weeds are a hassle for farmers, gardeners, property owners and landscape managers. Hand digging and mulching is the ‘go to’ method I use in my own garden, but this can be problematic for commercial crops and public open space. With the wealth of information now in the public domain about the health and environmental issues related to chemical herbicides for killing weeds, there is a major shift to adopting non-toxic weed control methods.

(Visit: www.weedtechnics.com).

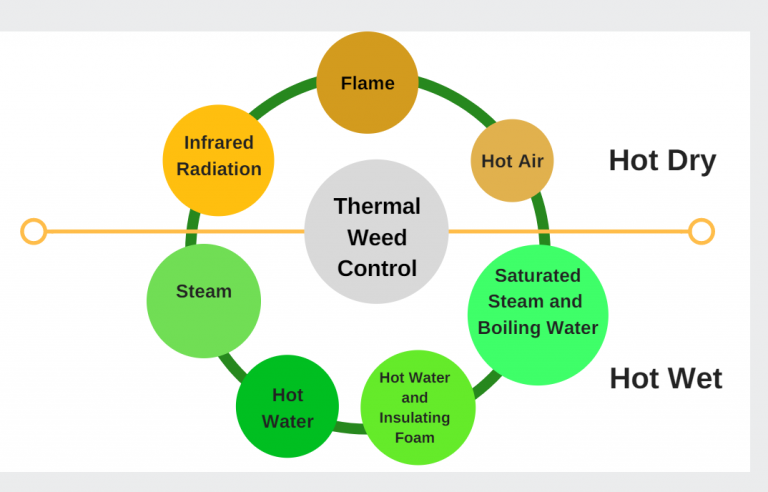

Steam weed control falls under the “Thermal Weed Control” category of non-toxic methods. These can be classified into Hot Dry and Hot Wet categories.

(Read more about the science at the base of the page.)

Beating plant adaptation

Most common soft wooded, annual and perennial weeds, by their nature, are plants that have migrated or been introduced from environments such as grasslands, prairies and forest floors. In their natural environment, they are grazed upon by ruminants and occasionally exposed to fire. They are adapted to growing back from the meristematic cells in the crown of the plant that sits at, or just below, the soil surface. Cutting weeds or using a flame or desiccant (vinegar or acid) mimics nature, which the weeds are adapted to. They draw on the stored energy in their roots to regenerate new shoots, often multiple shoots. A new vigorous flush of leaf growth starts the photosynthesis process of converting sunlight into sugars and energy to replenish and regrow their root system and energy storage. This can happen within days.

Hot wet methods of weed control enable a more rapid transfer of lethal heat into the cell structure of the weed.

What makes hot wet methods so effective, is that they are unlike any process that the weeds are adapted to. Hot wet methods of weed control enable a more rapid transfer of lethal heat into the cell structure of the weed. With hot wet methods, deeper penetration into the crown of the plants is achieved; than with mechanical cutting, flame or desiccants. The heated fluid penetrates and damages or destroys the growing tips, delaying the usual rapid regeneration experienced with dry thermal or mechanical cutting methods.

Pioneering

As the owner of a landscape contracting business, with a strong conviction that there should be an alternative to chemical weed control, I was motivated to find a way.

I have been developing hot wet weed control methods since about 1996. I am known as a steam weed killing expert or looney, depending on who you talk to. I started by having a small heat exchanger coil designed to heat water to make steam. We used an LPG gas cylinder with a burner flame to heat the steel tube through which we pumped superheated water. We pumped the water with a reclaimed espresso machine pump and wrapped the steam delivery hose in multiple layers of insulation, to keep the heat all the way through the 10m/ 30 feet of hose. I thought that I was on a real winner.

But the real problem with steam is that it rises and loses temperature in the air rapidly. Unless it’s under pressure, it is really hard to get it to hit the weeds that are on the ground. So, then we had to encapsulate the emitting steam in a metal shroud so that it was trapped in there to condense and cook the weeds. But the other problem with steam is that it is vapour and vapour loses its heat uber fast. It’s practically useless, for damaging plants, when it is less than 95° C/ 203° F. And it’s slow to penetrate plant tissue; so, I had to hold the cover over the weed for 4 seconds, unless it was a tough weed, which took 10 seconds.

Having full faith in my invention, in 1998 I tendered for and won the contract for, I believe, the world’s first council to have non-chemical weed control of all their footpaths and parks. Leichhardt Council in the inner west of Sydney. Well done Leichhardt Council at least 20 years of chem-free footpaths! With 175 kilometres (108 miles) of sidewalks to do, at 4 seconds a weed and a fixed contract price, I knew that I needed another plan.

I got into hot water

Losing money is a great motivator for change. Clearly steam wasn’t a solution. So I flew with one of my reporting managers across the country to meet with some other innovators who had developed a hot water weeding machine. I borrowed $90k and bought 2 machines and another $60k for trucks and tanks to put them on.

We went from using 15L (3¼ gal) of water per hour to 15L minute and 18kg of LPG (propane) gas a day to 70L diesel (15 gal) a day. Don’t worry – this was temporary!

But we improved productivity 10 fold and increased the longevity of the weed control by a factor of 3. That was a 30 times increase in total productivity. BUT the engineering of those prototype machines was a nightmare, and it just seemed that we still didn’t have enough temperature at the weed. We also had too much water running into gutters. I knew that somewhere between my super-efficient steamer and these monster hot water machines was an answer.

If it hadn’t been for the continuous breakdowns of those 2 hot water machines; I would not have met the co-inventors of the Satusteam™

method. Through their repair efforts and discussing the outcomes I was looking for, we established that in order to achieve maximum heat at the weed we needed to keep the water in a superheated state until it reached the weed. This could be done by having a restriction in the nozzle at the end of the lance in the applicator head. That would maintain the pressure of the water, and water under pressure has a higher boiling point than water at atmospheric pressure. But superheated water delivered at pressure through a restrictor nozzle expands into saturated steam at high pressure. The first time we tried it, we blasted dirt and mulch everywhere and more or less pressure blasted the weed into the soil. Not exactly a great result.

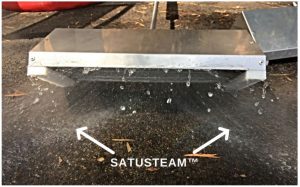

Then we had the Eureka moment. It was a unique, never-done-before idea: make a delivery system that allows the superheated water to depressurise; expand into saturated steam; lose its energy; coalesce in a chamber and be delivered to the weed as a low-pressure mixture of hot/boiling water and saturated steam.

The Saturated Steam weeding, Satusteam™ solution

Because the water is pressurised, it can be heated up to 115°-120°C/ 239°-248°F, without boiling. Pressurisation in our system raises the physical boiling temperature of water to over 300°C/572°F.

What this means is, that your superheated water doesn’t flash into saturated steam and boiling water (Satusteam™) until it is within 5cm /2” of the target. There is no time for it to cool in the atmosphere, the water droplets are large or turn into a stream of boiling water, therefore transferring maximum heat into the target vegetation.

The Satusteam™ system pressurises the water for 2 reasons. Firstly, it raises the physical boiling point of the water allowing superheating. Secondly, it allows us to use delivery hoses up to 100m/328′ from the boiler and still deliver Satusteam™ at 100°C/212°F.

This method reduced our water usage to 5L/minute (1¼ gal) and just 24L (6gal) a day of diesel for heating. We further improved productivity and were able to, for the first time, deliver a non chemical weed control solution that was productive and financially viable.

Depressurisation advantages

Our patented nozzle system depressurises the superheated water; to give a safe and controlled delivery. The ‘Satusteam™’ coats the vegetation rapidly at low pressure, which gives you great productivity. Satusteam™ does not displace mulch, compact soils, inject into desirable roots, damage soil structure; or splash operators.

I invested in designing the first Satusteam™ systems; sourcing motors for driving pumps and generating voltage; and sourcing burners and heat exchangers to deliver just the right amount of water. There was also the tasks of selecting appropriate pumps and hoses fit for purpose; and designing nozzles and applicator heads. All the custom designed and manufactured components were all small batch, high cost items.

We built the first Steamwand Phoenix in 2004 in Australia which was superseded by the SW (Satusteam™ Weeder) range in 2009. The Weedtecnics range continues to grow and develop.

We do not have a domestic sized machine, as we have focused on solutions for the larger urban and horticulture markets. There are now contractors across Australia and parts of the US and Canada; so your place could be kept weed-free, without you needing to buy a machine.

The science of hot methods of weed control

includes controlling weeds with infrared radiation, flame and hot air. They all use propane/ LPG as their heating source. There are a number of small flame units available which are comparatively portable and are used by homeowners, land-care groups and some cities. There are also larger ones such as HOAF and Sunburst with ride-on or tractor versions. There are some obvious limitations of using a blast of open flame to cook weeds. Dry leaf litter and grass easily catches alight and the flame melts rubber soft fall in playgrounds and rubber paving, it can’t be used on synthetic play surfaces and irrigation lines melt on contact.

My observational experience of using flame is that it doesn’t really penetrate the crown of the plants. It cooks off the top pretty effectively but regrowth from the crown is observed within a few days after treatment. This leads to having to treat frequently.Let me explain why this is the case. I remember when I was in the science lab at high school and we had Bunsen burners alight. My classmates and I would see how slowly we could pass our fingers through the flame. Despite feeling the heat, we didn’t end up with any blisters.

That is because as we passed our fingers through the flame we were exposed to dry heat and dry heat doesn’t linger. Whilst the temperature of the flame was in the vicinity of 1300° C / 2400° F the heat transfer of hot air and flame is quite slow and the air cools as soon as the flame or other radiant heat source moves on, or in the case of our fingers, they moved to cool air. When using a flame to cook weeds, in order to get better penetration and a consequently longer die back, the flame must be held in place for a period of time long enough for the soil around the root to heat up. The problem with this is that it increases the chance of fire and damage to the assets you are trying to protect by weeding. I have observed better results using flame in early morning when dew is present or after rain. For a start it’s safer, but I also reckon the water boiling on the leaves is retaining the heat for longer and transferring the heat into the leaves more efficiently.

Handheld and push-type flaming and radiant heat apparatus can be useful because of their portability but they come with high risk of off-target damage. Of the hot dry methods available, flame and radiant heat from ceramics or metal plates heated by flame are the most effective.

Hot Wet methods of weed control include steam, hot water, hot water and insulating foam and saturated steam and boiling water. Some hot wet methods are regarded as having superior control over weeds than hot dry methods. The reason for this is easily explained by comparing the Bunsen burner at 1300 °C/ 2400 °F to almost boiling water at 95 °C/ 203 °F. The devastating burns that occur when a cup of freshly brewed tea is spilt onto skin is a perfect example showing how the water transfers heat so effectively and intensifies the damage as it stays on the skin.

Satusteam™ delivers high temperature saturated steam and boiling water at a safe low pressure at the end of a cool-touch lance

Hot oil is even more effective as it doesn’t evaporate and heats to higher temperatures than water. People that work in kitchens learn soon enough that the worst burns are the hot, wet oil and water scalds, rather than the more localised burns from touching a hot dry pan or oven rack.

That’s thermal weed control in a nutshell.

Our clients are achieving savings and results with the Satusteam™ range of saturated steam and boiling water weed control systems.

Take a look at their results:

A Weedtechnics Experiment with The University of Colorado, Boulder

We want you to receive the benefits of others experience and be kept informed of interesting and helpful resources related to organic and holistic weed control. Simply contact us and we’ll do our best to achieve that.

Start steaming now and create a toxin-free environment for your community.

[/vc_column_text][vc_text_separator title=”Reach out to us if you have a any Questions!” i_icon_fontawesome=”fas fa-angle-double-down” i_color=”black” color=”green” border_width=”4″ css_animation=”zoomInLeft” add_icon=”true” css=”.vc_custom_1688529941620{background-image: url(https://www.weedtechnics.com/wp-content/uploads/2020/07/Flame-Thower-3.jpg?id=2872) !important;background-position: center !important;background-repeat: no-repeat !important;background-size: cover !important;}”][/vc_column][/vc_row][vc_row][vc_column css_animation=”fadeInUp” css=”.vc_custom_1688529840924{background-image: url(https://www.weedtechnics.com/wp-content/uploads/2020/07/Flame-Thower-1.jpg?id=2870) !important;background-position: center !important;background-repeat: no-repeat !important;background-size: cover !important;border-radius: 5px !important;}”]

Oops! We could not locate your form.

[/vc_column][/vc_row]